Underground & Under Pressure

Feeling the pressure? Hopefully not, because water pressure is safely tucked about four feet belowground in an earthy dirt-hug that’s engineered to protect it.

A water system is much more than strung together pipes belowground–even the most basic water system is a complex feat of engineering designed to evenly distribute water under pressure over a (potentially) large area.

So, what happens when waterlines are under pressure? One word: Expansion.

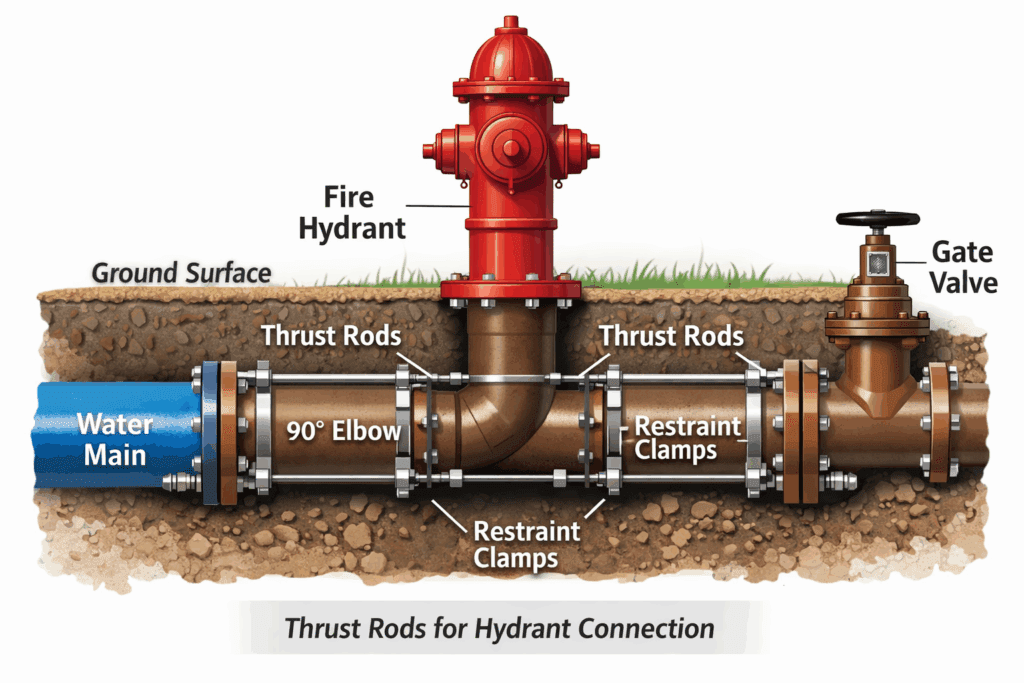

Water mains themselves are not typically one long, singular piece. Instead, they are line segments held together with couplers and heavy-duty bolted flanges capable of handling the water pressure with minimal leak loss. Anytime a pressurized water line changes direction or has a

point where pressure creates an unbalanced force, it naturally pushes against fittings, especially at corners or T-junctions, end points, or where fire hydrants poke above ground.

At these points, restraint is needed to keep the pipes from moving. Fire hydrants are a common example because of high, sudden flows—but the same physics applies elsewhere in the system. Without proper support, pressure can cause the pipe to push, shift, or even separate at joints. Support rods—often called thrust rods or restraints—are installed on either side of the hydrant to hold the pipe firmly in place and absorb that force.

A thrust block is also used to support a pipe in a corner or dead end of a line to minimize expansion. A thrust block is typically a piece of concrete (similar in look to a sidewalk paver) or poured concrete positioned to work with the weight of the packed earth above and beside the line to keep it stable.

By keeping the line from moving or expanding under pressure, these supports help prevent leaks, pipe breaks, and service disruptions.