More Than Meets the Eye: Transformers

Replacement or rebuilding of aging equipment allows the PUD to improve service reliability and save money on larger purchases like substation transformers.

During a Special Meeting of the BOC on March 14th, Jefferson PUD General Manager, Kevin Streett addressed the rebuild process for substation transformers and plans for the utility moving forward. (Overview begins at 1:20:26 in meeting)

A transformer is a large tank typically filled with several thousand gallons of mineral oil. At the center is a laminated core of high-grade steel that is tightly wound with a copper coil. The layers of core steel are specific to large transformers and often in short supply. When a short or “fault” occurs within a transformer it is often the winding within that is the culprit, not the core steel itself.

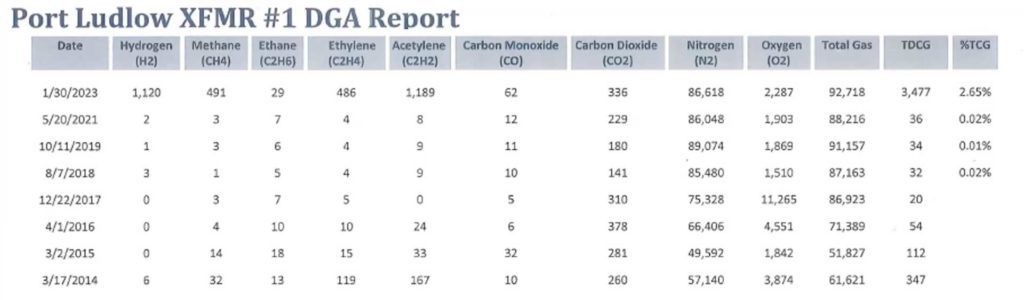

The mineral oil bath, which cools the internal components during use, often helps tell the tale of what type of fault has occurred within.

Substation crews sample oil from the transformer and use historical data sets, and interpretation of samples, to identify the likely cause of a fault. Disassembly of the damaged transformer by the refurbishing team is the final determination for the actual cause and extent of the damage.

The decision is then made to either refurbish the transformer or purchase a new transformer.

Lead time is a factor in this decision, with current turnaround for a refurbished transformer being approximately 12 months, while the timeline from order-to-delivery of a new transformer is estimated at 2 years.

Cost is another factor. Current estimates to refurbish the damaged Port Ludlow transformer is approximately $410,000. A new transformer costs approximately $700,000.

Standardization of transformers across the utility’s 9 substations is a long-term goal for the PUD, with 20MVA transformers being the go-to for each location. Long term system planning also includes multiple bays at substations like Port Ludlow. Port Ludlow substation currently has one transformer in operation with a second bay available. An additional bay allows for easier transfer of power should a major fault occur in the future.

The PUD looks to order a new 20MVA transformer to replace a smaller one in operation at the Quilcene substation. The transformer being sent for rebuild, upon completion, will be placed back into circulation at the Port Ludlow substation.