What’s that? Overhead Line Splice

The next time you’re on a county road, take a look down the length of utility poles and see if you spot something on the lines. No, it’s (hopefully) not a tree, or a bird, but rather it might be a small, in-line metal tube. What’s that?

Every time a tree branch or general wear and tear cause an overhead distribution line to break, or when a new line section is added, a splice is needed.

Line crew must determine whether to replace a damaged section of line entirely or use an overhead line splice–either way, a splice is what holds it all together in the field.

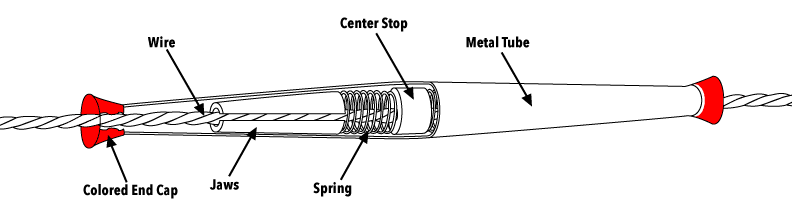

Overhead splices are a metal tube with tapered ends that securely holds each end of the severed utility line. Splice tubes act much like the classic finger trap kids toy–an object (the broken line) is inserted into one side and pressure is applied internally, making it very difficult to remove. The splice tube itself is approximately 12″-16″ long and features color-coded ends for easy reference of wire size.

Placing a line splice can be tricky, especially considering the conditions line crews work in during outages!

Line crew must determine (onsite) the level of fix needed when a line breaks. They must take into account the location of the break, the extent of damage to the line itself, and amount of sag or tension on the line. Sag for distribution lines is specific so utility poles can support the massive weight of the lines. Ensuring there is enough excess material in the line to allow for a line splice is essential.

To fix the break, crew attach a special come-along ratchet system to each broken end of line. The come-along devise pulls the lines closer together and allows the crew to safely work at the break point either on the ground or in the air from their bucket truck.

Trees are notorious for not being delicate, so the jagged ends of the line are cut square and thoroughly cleaned. The freshly cleaned wire is then inserted into the splice on each end. Spring loaded jaws set it into place, and act as the conductive surface power flows through. Line crew then use an automatic crimper to apply additional tension. The line is then re-tensioned and re-energized.

Overhead splices save time and operational expense by keeping good working utility lines in the air.