What’s that? Downguy

Everything needs a helping hand from time to time, even utility poles.

At first glance, utility poles themselves appear stout, but consider that utility lines for a single span (distance from pole-to-pole) can weigh hundreds, if not thousands of pounds, and you’ll quickly realize poles need all the help they can get. Enter the engineering marvel known as the “downguy”.

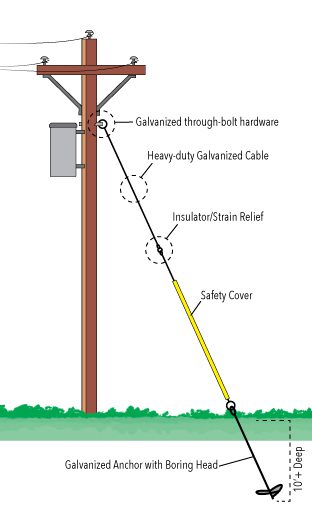

What is a downguy? It’s a term used for an assembly anchoring pole-to-earth composed of a thick galvanized steel cable that is diagonally anchored to the ground from the top section of a pole. Connecting to the top of the pole helps provide the best leverage. Galvanized materials are used due to their rust and corrosion resistance.

The “Guy Line” is the visible steel cable which is connected to an anchor. The anchor is chosen based upon the anticipated load the pole must withstand. Larger transmission poles (those extending upward of 80’+ into the air) may require multiple downguy assemblies and engineered anchors.

Distribution poles, like those commonly found in neighborhoods and along roadways, often use a screw-style anchor. The anchor end resembles a simple boat propeller connected to a long, galvanized rod with a large eyelet. Anchors are often 10’ long or longer to ensure adequate holding power. The steel cable from the top of the pole is tensioned to the large eyelet once the anchor is set.

Placing the screw-like anchor can be a challenge because utility poles can be in some less than desirable locations beside roadways or cross-country—and anchor points can be even worse. To screw an anchor down many feet deep requires a lot of torque and is a job for the utilities Derrick Digger truck.

Derrick Diggers are commonly used to bore and place utility poles in the field. This full-size line truck features a large auger bit connected to an extendable armature. The bit can be removed, and a coupler used to connect to the top of the screw-style downguy anchor. Through careful guidance by the line crew, the anchor is positioned and slowly churns into the ground. Crew monitor the angle to ensure maximum holding power as the Derrick Digger rotates it to the correct depth.

Larger transmission poles can feature anchors set by an excavator. To do this, a large channel is dug down to the correct depth, and the anchor is placed inside. The weight of the backfilled dirt and rock supply tension to support the pole.

A come-along device is used by the line crew to tension the steel cable, and the strength of the Derrick Digger can be used to assist with moving the pole into the proper position while the downguy is being tensioned.

The cable itself features an in-line insulator/strain relief. Being a steel cable, and in proximity to high voltage, the insulator acts to isolate the downguy from accidental grounding, while the strain relief helps distribute tension evenly.

In areas where placing a downguy is impossible, say along a steep sloping roadway or around sidewalks where head clearance issues exist, engineered downguy assemblies can be used. This often includes the use of a secondary, shorter pole mounted nearby. The downguy transfers the load via the guy wire to the secondary pole which, in turn, has its own anchored downguy.

In pedestrian areas, a simple galvanized arm is mounted to the pole to offset the downguy. The rod extends 90 degrees from the pole and supports the tension while allowing safe travel below.

A plastic guard is often placed near the bottom section of the cable to prevent passersby from running into it.