What’s that? Line Insulators

If large transmission poles are the backbone of our local grid, the small, ribbed insulators near the top would act as the fingers that hold it all together—at a safe distance.

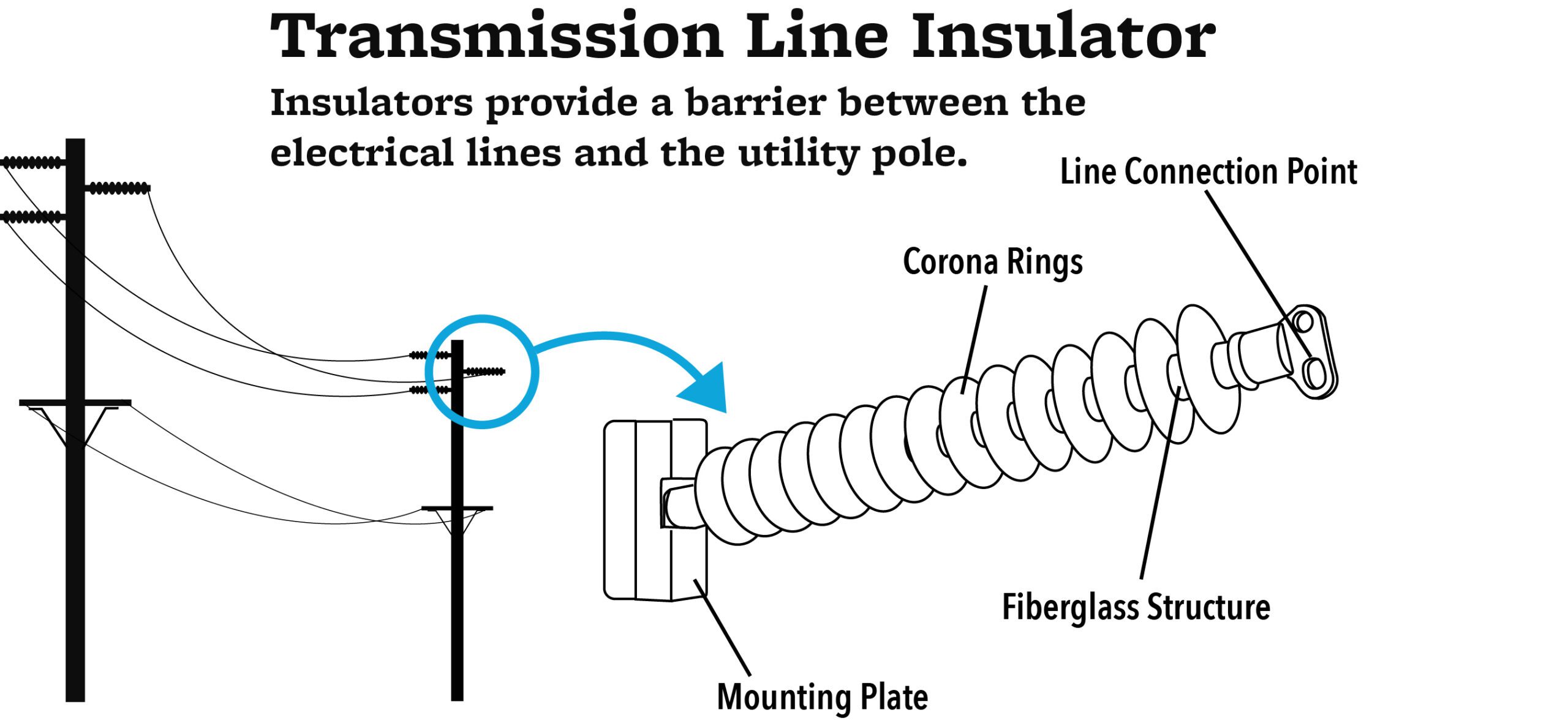

Insulators come in all shapes, sizes and materials, but regardless of all these factors they have one primary goal: keep the supported lines from energizing the pole.

Insulators are made from a non-conductive material—in modern day this is typically a polymer of resin-based product like fiberglass. Polymer insulators are much lighter in weight than those used just two decades ago plus the added ability to shed water (and not wear from salt water), their shatter resistance, and the overall cost is far cheaper. The backbone of a modern insulator is typically reinforced fiberglass which helps keep weight down to about 40-50lbs.

In the past, porcelain and glass insulators were widely used due to easy manufacturing, but they were heavy and could be brittle under heavy loads and harsh conditions. Porcelain insulators could weigh nearly 2/3 more than modern polymer models. A major shift to polymer insulators began in the 1980s, and today they dominate the market. Old porcelain and glass insulators are now often found in junkyards or swap meets—and smaller ones make great desk ornaments.

Ok, so they keep me from getting shocked when I touch a utility pole…but what are the little disc-ribs for?

The discs are called corona rings, and they help spread out the electric field. At high voltages (like the 115,000-volt JPUD transmission lines), electricity can ionize the air near sharp edges or uneven surfaces which can create a buzzing sound and energy loss. The corona rings help even out this voltage and can actually help extend the life of the insulator. The number of rings is dependent on the voltage level and electrical stress they need to manage.

So, how long do they last?

Newer polymer transmission line insulators have a typical lifespan of 25-30 years but can last up to 40 under ideal conditions. This is a little shorter than the porcelain and glass, which can last 45-60 years.

So next time you spot a transmission tower, look for the little disks keeping the lines in check, they’re tiny, but mighty.